Our Projects

Examples of Projects Successfully Delivered:

New Control System for Ulma Flow-Wrapper

New PLC software package developed for an Ulma PV350 box-motion flow-wrapper, as part of a full refurbishment in our workshop.

Our touch-screen system added a new lease of life and made operation and fault-finding a breeze, with new easy-to-navigate graphical screens tailored to the customer and useful help texts.

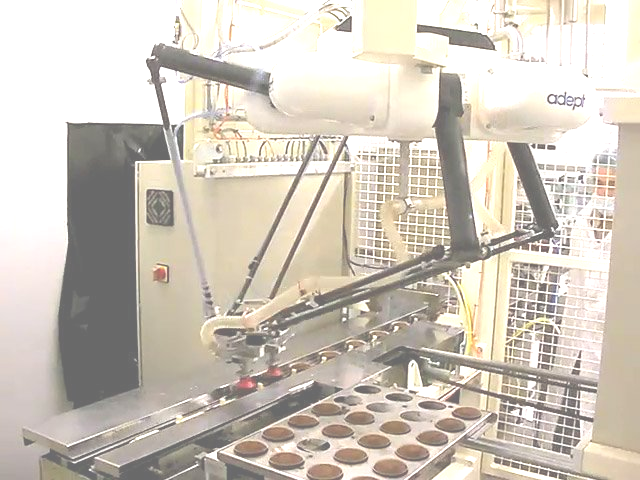

Robotic Pick & Place

Repetitive or intricate tasks can be automated, bringing benefits such as consistency, speed, labour cost savings and safety.

We carefully study existing manual operations and design-in technologies such as vision, special product grippers and connection to 3rd party machines, so that we offer innovative solutions with real benefits and a quick return-on-investment

Pictured: Muffin line - Quattro robot picking product in 2's from tray and loading to flow-wrapper.

Counting & Carton Filling

Firelighters exiting the wrapper, at speeds of 400ppm, are counted into cartons, in groups of 4 at a time.

This previously laborious task was taking up seven operatives.

With the machine in place the only three operatives could run the line, providing a return on investment of just a few months.

Refurbishment and New Electronics

Mechanical machines can be refitted with Servo-driven solutions to give high performance, greater functionality and reduced maintenance.

If your machinery is old/worn/due for replacement/out-of-date electronics - You may not need to buy new.

We can Refurbish many types of machinery at our workshop, replace mechanical parts and mechanisms, new control systems, clean up, repaint and fully test, ready for return to you. Contact us to discuss your requirements.

Pictured: Jaguar wrapper fully refurbished with electronic controls, & touch-screen.

Multi-Head Weigher Line

Installation of a new multi-head-weigher, replacing an old system that could no longer be supported. The full project included removal of the old weigher, modifications to the gantry and the surrounding machinery and integration into the existing packaging line and full commissioning.

Assembly Lines for Parts Manufacturing

Operator workload is eliminated through intelligent software.

The machine performs intricate assembly operations at each of the 12 stations.

Software tracks the progress of each part, minimising the waste and stoppage time by detecting loading problems and ejecting the part automatically.

Theatre Automation

Software development and commissioning of over 60 axes as part of a major West-End show.

System comprises Scada, PLCs & motion controls, to smoothly control combinations of cable driven servos and hydraulics in multiple master/slave configurations.

Welding with Robots

For the manufacture of parts used in rolling stock, MD Automation provided the controls and developed software for a 3 axis welding lathe with graphical program editing: CNC functionality without the cost!

Tub Filling Line for Pet Foods

Integrated into a multi-head weigher, this allowed the customer to fill weighed portions directly into tubs, making a significant space and cost saving compared to buying a separate line.